2005 Ski-Doo Racing Handbook, Page 108Get this manual

SECTION 04SUSPENSION SC-3 SC-4RAS

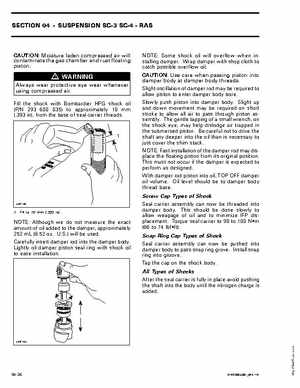

CAUTION: Moisture laden compressed air will contaminate the gas chamber and rust floating piston

NOTE: Some shock oil will overflow when installing damperWrap damper with shop cloth to catch possible overflow oilCAUTION: Use care when passing piston into damper body at damper body threadsSlight oscillation of damper rod may be required to allow piston to enter damper body boreSlowly push piston into damper bodySlight up and down movement may be required on short stroke to allow all air to pass through piston assemblyThe gentle tapping of small wrench, on the shock eye, may help dislodge air trapped in the submersed pistonBe careful not to drive the shaft any deeper into the oil than is necessary to just cover the shim stackNOTE: Fast installation of the damper rod may displace the floating piston from its original positionThis must not occur if the damper is expected to perform as designedWith damper rod piston into oil, TOP OFF damper oil volumeOil level should be to damper body thread baseScrew Cap Types of Shock Seal carrier assembly can now be threaded into damper bodyThis should be done slowly to allow weapage of oil and to minimize IFP displacementTorque seal carrier to 90 to 100 Nm (66 to 74 lbfft)Snap Ring Cap Types of Shock Seal carrier assembly can now be pushed into damper body to pass snap ring groveInstall snap ring into grooveTap the cap on the shock bodyAll Types of Shocks After the seal carrier is fully in place avoid pushing the shaft into the body until the nitrogen charge is added