2005 Ski-Doo Racing Handbook, Page 57Get this manual

SECTION 03CHASSIS PREPARATION

After recharging is complete and before installing the spring the rebuilt shock should be bench-testedStroke the shock to ensure full travel and smooth compression and rebound actionIf the shaft moves in or out erratically this could indicate too much air is trapped insideIf the shaft will not move or has partial travel then it may be hydraulically lockedIn either event the shock must be rebuilt againPay particular attention to the placement of the IFP, quantity of oil and shim stackpiston assembly1

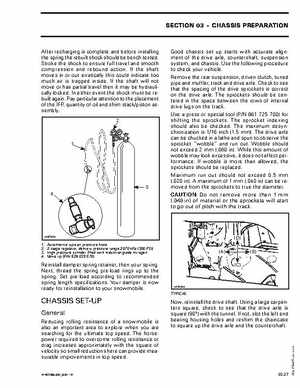

Good chassis set up starts with accurate alignment of the drive axle, countershaft, suspension system, and chassisUse the following procedure to check your vehicle: Remove the rear suspension, driven clutch, tuned pipe and muffler, track and drive axleCheck to see that the spacing of the drive sprockets is correct on the drive axleThe sprockets should be centered in the space between the rows of internal drive lugs on the trackUse press or special tool (PN 861 725 700) for shifting the sprocketsThe sprocket indexing should also be checkedThe maximum desynchronization is 116 inch (1.5 mm)The drive axle can be chucked in lathe and spun to observe the sprocket "wobble" and run outWobble should not exceed mm (.080 in)While this amount of wobble may look excessive, it does not affect performanceIf wobble is more than allowed, the sprockets should be replacedMaximum run out should not exceed 0.5 mm (.020 in)A maximum of mm (.040 in) can be removed from the sprockets to true the diameterCAUTION: Do not remove more than mm (.040 in) of material or the sprockets will start to go out of pitch with the track