2004 Ski-Doo Elite Factory Service Manual, Page 205Get this manual

Section 05 ENGINE MANAGEMENT Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

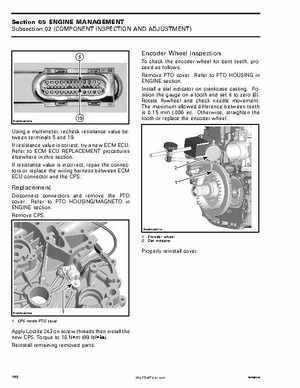

Encoder Wheel Inspection

To check the encoder wheel for bent teeth, proceed as followsRemove PTO coverRefer to PTO HOUSING in ENGINE sectionInstall dial indicator on crankcase castingPosition the gauge on tooth and set it to zero (0)Rotate flywheel and check needle movementThe maximum allowed difference between teeth is 0.15 mm (.006 in)Otherwise, straighten the tooth or replace the encoder wheel

R1503motr182A

Using multimeter, recheck resistance value between terminals and 19If resistance value is correct, try new ECM ECURefer to ECM ECU REPLACEMENT procedures elsewhere in this sectionIf resistance value is incorrect, repair the connectors or replace the wiring harness between ECM ECU connector and the CPS