2002 Ski-Doo Shop Manual Volume Three, Page 146Get this manual

Subsection 04

Section 04 ENGINE (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

RINGPISTON GROOVE CLEARANCE

Using feeler gauge check clearance between rectangular ring and grooveReplace piston if clearance exceeds specified toleranceRefer to TECHNICAL DATA

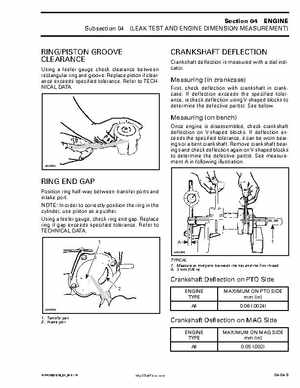

CRANKSHAFT DEFLECTION

Crankshaft deflection is measured with dial indicator

Measuring (in crankcase)

First, check deflection with crankshaft in crankcaseIf deflection exceeds the specified tolerance, recheck deflection using V-shaped blocks to determine the defective part(s)See below

Measuring (on bench)

Once engine is disassembled, check crankshaft deflection on V-shaped blocksIf deflection exceeds the specified tolerance, it can be worn bearings or bent crankshaftRemove crankshaft bearings and check deflection again on V-shaped blocks to determine the defective part(s)See measurement in following illustrationA01C0PA