2002 Ski-Doo Shop Manual Volume One, Page 117Get this manual

Section 04 ENGINE Subsection 03 (443 AND 503 ENGINE TYPES)

TROUBLESHOOTING

Before completely disassemble engine, check airtightnessRefer to LEAK TEST AND ENGINE DIMENSION MEASUREMENTNOTE: The following procedures can be done without removing the engine from chassis

CLEANING

Discard all gasketsUse Gasket Remover (PN 413 708 500) to clean mating surfacesClean all metal components in non-ferrous metal cleanerScrape off carbon formation from cylinder exhaust port, cylinder head and piston dome using wooden spatulaNOTE: The letters "AUS" and arrow on the piston dome must be visible after cleaningClean the piston ring grooves with groove cleaner tool, or with piece of broken ring

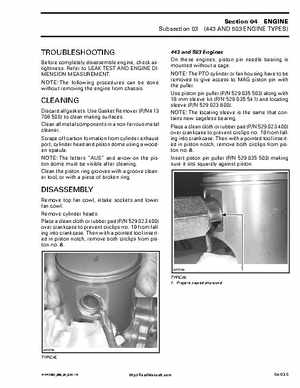

443 and 503 Engines On these engines, piston pin needle bearing is mounted without cageNOTE: The PTO cylinder or fan housing have to be removed to give access to MAG piston pin with the pullerUse piston pin puller (PN 529 035 503) along with 18 mm sleeve kit (PN 529 035 541) and locating sleeve (PN 529 023 800)NOTE: The locating sleeve is the same that contains new cageless bearingPlace clean cloth or rubber pad (PN 529 023 400) over crankcase to prevent circlips no10 from falling into crankcaseThen with pointed tool inserted in piston notch, remove both circlips from piston no8Insert piston pin puller (PN 529 035 503) making sure it sits squarely against piston