2001 Ski-Doo Factory Shop Manual Volume One, Page 168Get this manual

Subsection 10

Section 04 ENGINE (CARBURETOR AND FUEL PUMP)

CLEANING AND INSPECTION

The entire carburetor should be cleaned with general solvent and dried with compressed air before disassemblyCAUTION: Heavy duty carburetor cleaner may be harmful to the float material and to the rubber parts, O-rings, etcTherefore, it is recommended to remove those parts prior to cleaningCarburetor body and jets should be cleaned in carburetor cleaner following manufacturer's instructions

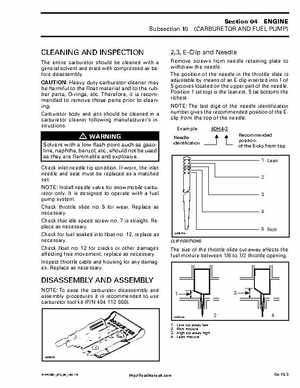

2,3, E-Clip and Needle

Remove screws from needle retaining plate to withdraw the needleThe position of the needle in the throttle slide is adjustable by means of an E-clip inserted into of grooves located on the upper part of the needlePosition (at top) is the leanest, (at bottom) the richestNOTE: The last digit of the needle identification number gives the recommended position of the Eclip from the top of the needleExample Needle identification 6DH4-3 Recommended positionof the E-clip from top

WARNING

Solvent with low flash point such as gasoline, naphtha, benzol, etc should not be used as they are flammable and explosiveCheck inlet needle tip conditionIf worn, the inlet needle and seat must be replaced as matched setNOTE: Install needle valve for snowmobile carburetor onlyIt is designed to operate with fuel pump systemCheck throttle slide no5 for wearReplace as necessaryCheck that idle speed screw no7 is straightReplace as necessaryCheck for fuel soaked into float no12; replace as necessaryCheck float no12 for cracks or other damages affecting free movement; replace as necessaryInspect throttle cable and housing for any damagesReplace as necessary