1999 Ski-Doo Factory Shop Manual Volume Three, Page 113Get this manual

Subsection 03

Section 04 ENGINE (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

LEAK TEST AND ENGINE DIMENSION MEASUREMENT 0

LEAK TEST

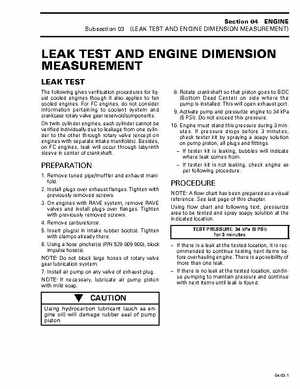

The following gives verification procedures for liquid cooled engines though it also applies to fan cooled enginesFor FC engines, do not consider information pertaining to coolant system and crankcase rotary valve gear reservoircomponentsOn twin-cylinder engines, each cylinder cannot be verified individually due to leakage from one cylinder to the other through rotary valve (except on engines with separate intake manifolds)Besides, on FC engines, leak will occur through labyrinth sleeve in center of crankshaft8Rotate crankshaft so that piston goes to BDC (Bottom Dead Center) on side where the pump is installedThis will open exhaust port9Activate pump and pressurize engine to 34 kPa (5 PSI)Do not exceed this pressure10Engine must stand this pressure during minutesIf pressure drops before minutes, check tester kit by spraying soapy solution on pump piston, all plugs and fittings If tester kit is leaking, bubbles will indicate where leak comes from If tester kit is not leaking, check engine as per following procedure