1997 Ski-Doo Factory Shop Manual Volume Two, Page 305Get this manual

Section 08 BODYFRAME Sub-Section 02 (BODY)

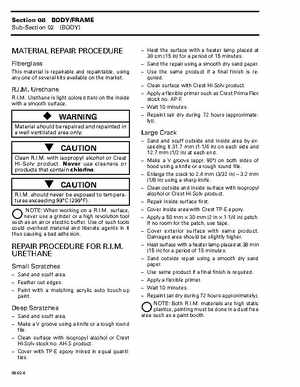

MATERIAL REPAIR PROCEDURE

Fiberglass

This material is repairable and repaintable, using any one of several kits available on the market

R.I.MUrethane

R.I.MUrethane is light colored (tan) on the inside with smooth surface-

WARNING

Material should be repaired and repainted in well ventilated area only

Heat the surface with heater lamp placed at 38 cm (15 in) for period of 15 minutes Sand the repair using smooth dry sand paper Use the same product if final finish is required Clean surface with Crest Hi-Solv product Apply flexible primer such as Crest Prima Flex stock noAP-F Wait 10 minutes Repaint (air dry during 72 hours (approximately))

Large Crack

Sand and scuff outside and inside area by exceeding it 31.7 mm (1-14 in) on each side and 12.7 mm (12 in) at each end Make groove (appr90) on both sides of hood using knife or rough round file Enlarge the crack to 2.4 mm (332 in) 3.2 mm (18 in) using sharp knife Clean outside and inside surface with isopropyl alcohol or Crest Hi-Solv product Repair inside surface first Cover inside area with Crest TP-E epoxy Apply 50 mm 30 mm (2 in 1-14 in) patchIf no room for the patch, use tape Cover exterior surface with same productDamaged area should be slightly higher Heat surface with heater lamp placed at 38 mm (15 in) for period of 15 minutes Sand outside repair using smooth dry sand paper Use same product if final finish is required Apply flexible primer Wait 10 minutes Repaint (air dry during 72 hours approximately)NOTE: Both R.I.Mmaterials are high static plastics, painting must be done in dust free area such as paint booth