1997 Ski-Doo Factory Shop Manual Volume Three, Page 65Get this manual

Sub-Section 02

Section 03 ENGINE (599, 699 AND 809 ENGINE TYPES)

ASSEMBLY

2,3, Crankshaft Bearing, Anti-seize Lubricant and Labyrinth Sleeve

Smear anti-seize lubricant (PN 413 7010 00) on part of crankshaft where bearing fitsPrior to installation, place bearings into an oil container filled with oil previously heated to 75C (167F)This will expand bearing and ease installation

809 Engine Only Last PTO bearing is mm (516 in) from inner bearing

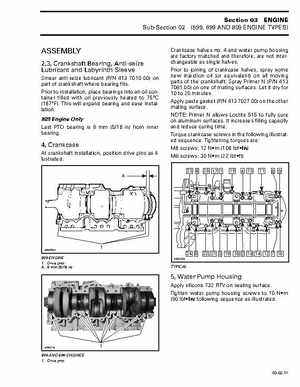

4, Crankcase

At crankshaft installation, position drive pins as illustratedCrankcase halves no4 and water pump housing are factory matched and therefore, are not interchangeable as single halvesPrior to joining of crankcase halves, spray some new injection oil (or equivalent) on all moving parts of the crankshaftSpray Primer (PN 413 7081 00) on one of mating surfacesLet it dry for 10 to 20 minutesApply paste gasket (PN 413 7027 00) on the other mating surfaceNOTE: Primer allows Loctite 515 to fully cure on aluminum surfacesIt increases filling capacity and reduce curing timeTorque crankcase screws in the following illustrated sequenceTightening torques are: M6 screws: 12 Nm (106 Ibfin) M8 screws: 30 Nm (22 Ibfft)