1989 Ski-Doo Repair Manual, Page 79Get this manual

Section 02 Sub-section 03

(377 ENGINE TYPE)

Prior to installing, place bås into an oil container filled with oil heated to 75C (167FIThis will expand bearings and ease installationInstall bearings with groove as per exploded viewBearings are pressed on crankshaft ",ntil they rest against the radi",sThis radius maintains the gap needed for bearing lubrication

NOTE: Prior to applying LDcti1e 515 i1 is possible to use primer (PIN 413705300) or primer NF (P IN 413 7024 001This increases cure speed and gap filling capabilityRefer to supplier instructionsPosition crankcase halves together and tighten screws

by handThen install and tighten armature plate on mag-

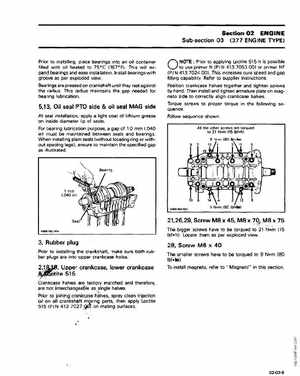

neto side to correctly align crankcase halvesTorque screws to proper torq",e in the following sequenceFollow sequence shownAll the other SCIe'NS are torqued to 21 N.m C15 Ibf.ttl

5,13, Oil seal PTO sideoil seal MAG side

At seal installation, apply light coat of lithium grease on inside diameter lip of sealsFor bearing lubrication porpose, gap of 1.0 mm (,040 in) must be maintained between seals and bearingsWhen installing plain seals (without locating ring or without spacing legs!, ensure to maintain the specified gap as illustrated