1982 Ski-Doo Shop Manual, Page 90Get this manual

SECTION 02 ENGINE SUB-SECTION 05 (464 ENGINE TYPE)

CLEANING

Discard all oil seals, gaskets, "0" rings and sealing rings Clean all metal components in non-ferrous metal cleanerRemove old "Loctite" from crankcase mating surfaces with Bombardier sealant stripper_ CAUTION: Never use sharp object to scrapeaway old sealant as score marks incurred are detrimental to crankcase sealing

ASSEMBLY

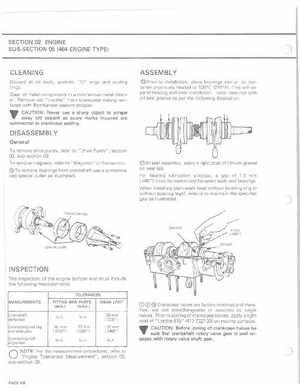

Prior to installation, place bearings into an oil container previously heated to 100 (210 F)This will expand bearing and ease installationInstall bearings with oil seal groove as per the following illustration

DISASSEMBL Y

General

To remove drive pulley, refer to "Drive Pulley", section 03, sub-section 03To remove magneto, refer to "Magneto" in this section

To remove bearings from crankshaft use protective

cap special puller as illustrated

At seal assembly, apply light coat of lithium grease on seal lipsFor bearing lubrication purpose, gap of 1.0 mm (,040") must be maintained between seals and bearingsWhen installing plain seals (seal without locating ring or without spacing legs), ensure to maintain the specified gap as illustrated