1978 Ski-Doo Shop Manual, Page 232Get this manual

SECTION 04 SUB-SECTION 05, (CARBURETOR)

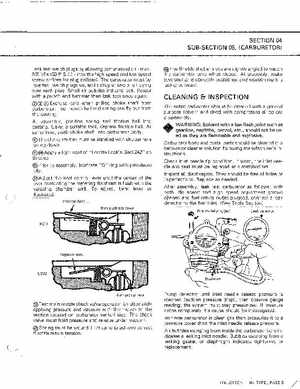

Leak test welch plugs by allowing compressed airmax345 kPa (50 P.S.Iinto the high speed and low speed screw orifices (or plug orifices)The carburetor must be inverted, welch plugs up, and drop or two of oil laying over each plugSmall air bubbles indicate leakReseal with punch and hammer then leak test once again

The throttle shutter sides are slightly angled to match

the carburetor bore when closedAt assemblymake sure shutter is correctly positioned and location mark is facing outward

000 Exercise care

CLEANINGINSPECTION

The entire carburetor should be cleaned with general purpose solvent and dried with compressed air before disassemblyWARNING: Solvent with low flash point such as gasoline, naphtha, benzol, etc should not be used as they are flammable and explosiveCarburetor body and metal parts should be cleaned in carburetor cleaner solution following manufacturer's instructionsCheck inlet needle tip conditionIf worn, the inlet needle and seat must be replaced as matched setInspect all diaphragmsThey should be free of holes or imperfectionsReplace as neededAfter assembly, leak test carburetor as follows: with both idle speed and high speed adjustment screws opened and fuel return outlet plugged, connect leak detector to the fuel inlet(See Tools Section)Fuel outlet plugged