1978 Ski-Doo Shop Manual, Page 42Get this manual

:-_-_ SECTION 02 SUB-SECTION 03 (DRIVE PULLEY)

(Inside of sliding half should be cleaned with clean clothThe square shaft can be cleaned with fine steel wool and clean cloth

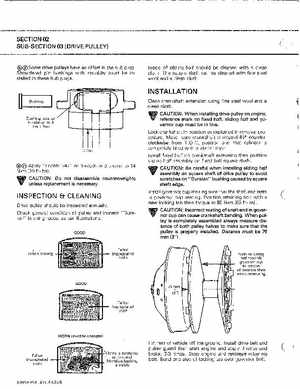

Some drive pulleys have an offset in the hub plugShouldered pin bushings with shoulder must be installed in these hub plugs

INSTALLATION

Clean crankshaft extension using fine steel wool and clean clothBushing location in relation with the offset

CAUTION: When installing drive pulley on engine, reference mark on fixed half, sliding half and governor cup must be in lineLock crankshaft in position as explained in removal procedureMake sure crankshaft is rotated 45 counterclockwise from T.D.Cposition and that cylinder is completely filled with starter ropeInstall fixed half on crankshaft extension then position sliding half assembly on fixed half square shaft

Apply "Loctite 242" on threads and torque to 14

Nom (10 ft-IbslCAUTION: Do not disassemble counterweights unless replacement is necessary

CAUTION: Be careful when installing sliding half assembly on square shaft of drive pulley to avoid scratches onDuralon" bushing caused by square shaft edgeInstall governor cup making sure that the shaft end rests in governor cup seatingPosition retaining bolt with new locking tab then torque to 85 Nom (63 ft-lbs)CAUTION: Incorrect seating of shaft end in governor cup can cause crankshaft bendingWhen pulley is completely assembled always measure distance of both pulley halves to make sure that the pulley is properly installedDistance must be 76 mm (3")