Bombardier SeaDoo 2001 factory shop manual, Page 233Get this manual

Subsection 03

Section 06 ENGINE MANAGEMENT (DI) (COMPONENT INSPECTION AND ADJUSTMENT)

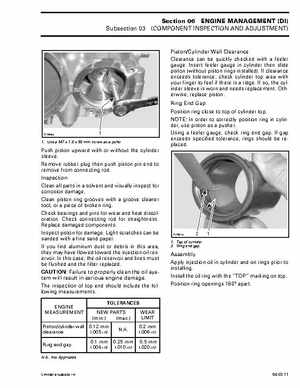

PistonCylinder Wall Clearance Clearance can be quickly checked with feeler gaugeInsert feeler gauge in cylinder then slide piston (without piston rings installed)If clearance exceeds tolerance, check cylinder top area with your finger to feel if there is ridgeIf so, the cylinder sleeve is worn and needs replacementOtherwise, replace pistonRing End Gap Position ring close to top of cylinder topNOTE: In order to correctly position ring in cylinder, use piston as pusherUsing feeler gauge, check ring end gapIf gap exceeds specified tolerance, rings should be replaced

F12R06A

1Use M7 1.0 50 mm screw as puller

Push piston upward with or without the cylinder sleeveRemove rubber plug then push piston pin end to remove from connecting rodInspection Clean all parts in solvent and visually inspect for corrosion damageClean piston ring grooves with groove cleaner tool, or piece of broken ringCheck bearings and pins for wear and heat discolorationCheck connecting rod for straightnessReplace damaged componentsInspect piston for damageLight scratches can be sanded with fine sand paperIf you find aluminum dust or debris in this area, they may have flowed toward the injection oil reservoirIn this case, the oil reservoir and lines must be flushed and the filter replacedCAUTION: Failure to properly clean the oil system will result in serious engine damageThe inspection of top end should include the following measurementsENGINE MEASUREMENT Pistoncylinder wall clearance Ring end gap