Bombardier SeaDoo 2000 factory shop manual volume 2, Page 114Get this manual

Section 04 ENGINE Subsection 07 (EXHAUST SYSTEM)

Use compressed air at 124 kPa (18 PSI) to pressurize tuned pipeNOTE: Prior to verifying leaks, plug all holes and pressurize tuned pipe while immerging it in waterCAUTION: Always ensure water passages are not blocked partially or completely while welding tuned pipe

INSTALLATION

Installation is essentially the reverse of removal proceduresHowever, pay particular attention to the following

Exhaust Manifold

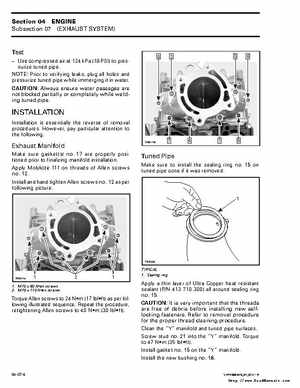

Make sure gasket(s) no17 are properly positioned prior to finalizing manifold installationApply Molykote 111 on threads of Allen screws no12Install and hand tighten Allen screws no12 as per following picture

F06D1YB

Tuned Pipe

Make sure to install the sealing ring no15 on tuned pipe cone if it was removed