Bombardier SeaDoo 2000 factory shop manual volume 2, Page 37Get this manual

Subsection 02

Section 02 MAINTENANCE (PERIODIC INSPECTION CHART)

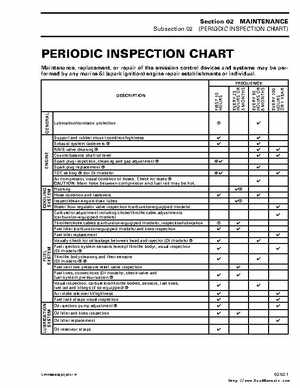

PERIODIC INSPECTION CHART

FREQUENCY EVERY 25 HOURS OR MONTHS EVERY 50 HOURS OR MONTHS DESCRIPTION

EVERY 100 HOURS OR YEAR

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any marine SI (spark ignition) engine repair establishments or individual

GENERAL

Lubricationcorrosion protection Support and rubber mount conditiontightness Exhaust system fasteners RAVE valve cleaning Counterbalance shaft oil level Spark plug inspection, cleaning and gap adjustment Spark plug replacement TDC setting (for DI models) Air compressor, visual condition of hosesCheck for leaks CAUTION: Main hose between compressor and fuel rail may be hotFlushing Hose condition and fasteners Inspectclean engine drain tubes Water flow regulator valve inspection (carburetor-equipped models) Carburetor adjustment including chokethrottle cable adjustments (carburetor-equipped models) Throttlechoke cables (carburetor-equipped models), inspectionlubrication Fuel filter (carburetor-equipped models) and lines inspection Fuel filter replacement Visually check for oil leakage between head and injector (DI models) Fuel injection system sensors (except throttle body), visual inspection (DI models) Throttle body cleaning and their sensors (DI models) Fuel vent line pressure relief valve inspection Fuel lines, connections (DI models), check-valve and fuel system pressurization Visual inspection: carburetorsthrottle bodies, sensors, fuel lines, fuel rail and fittings (if so equipped) Air intake silencer fittightness Fuel tank straps visual inspection Oil injection pump adjustment Oil filter and lines inspection Oil filter replacement Oil reservoir straps