Bombardier SeaDoo 2000 factory shop manual volume 2, Page 15Get this manual

INTRODUCTION

Standard Thread Repair 1Follow instructions on Loctite FORM-A-THREAD (PN 413 708 600) package2If plate is used to align bolt: aApply release agent on mating surfacesbPut waxed paper or similar film on the surfaces3Twist bolt when inserting it to improve thread conformationNOTE: NOT intended for engine stud repairs Repair of Small HolesFine Threads Option 1: Enlarge damaged hole, then follow Standard Thread Repair procedureOption 2: Apply FORM-A-THREAD on the screw and insert in damaged holePermanent Stud Installation (light duty) 1Use stud or thread on desired length2DO NOT apply release agent on stud3Do Standard Thread Repair4Allow to cure for 30 minutes5Assemble

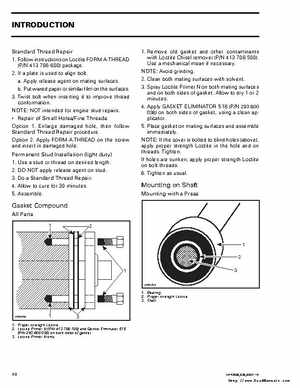

1Remove old gasket and other contaminants with Loctite Chisel remover (PN 413 708 500)Use mechanical mean if necessaryNOTE: Avoid grinding2Clean both mating surfaces with solvent3Spray Loctite Primer on both mating surfaces and on both sides of gasketAllow to dry or minutes4Apply GASKET ELIMINATOR 518 (PN 293 800 038) on both sides of gasket, using clean applicator5Place gasket on mating surfaces and assemble immediatelyNOTE: If the cover is bolted to blind holes (above), apply proper strength Loctite in the hole and on threadsTightenIf holes are sunken, apply proper strength Loctite on bolt threads6Tighten as usual