Bombardier SeaDoo 2000 factory shop manual volume 1, Page 126Get this manual

Section 04 ENGINE Subsection 06 (BOTTOM END)

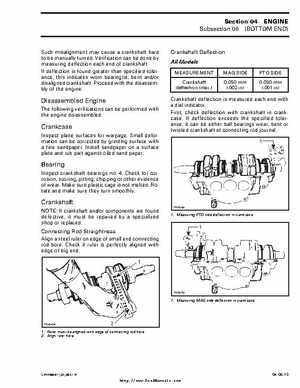

Such misalignment may cause crankshaft hard to be manually turnedVerification can be done by measuring deflection each end of crankshaftIf deflection is found greater than specified tolerance, this indicates worn bearing(s), bent andor disaligned crankshaftProceed with the disassembly of the engine

Crankshaft Deflection All Models

MEASUREMENT Crankshaft deflection (max MAG SIDE 0.050 mm (.002 in) PTO SIDE 0.030 mm (.001 in)

Disassembled Engine

The following verifications can be performed with the engine disassembled

Crankcase

Inspect plane surfaces for warpageSmall deformation can be corrected by grinding surface with fine sandpaperInstall sandpaper on surface plate and rub part against oiled sand paper

Crankshaft deflection is measured each end with dial indicatorFirst, check deflection with crankshaft in crankcaseIf deflection exceeds the specified tolerance, it can be either ball bearings wear, bent or twisted crankshaft at connecting rod journalBearing