Bombardier SeaDoo 1997 factory shop manual, Page 135Get this manual

Section 05 FUEL SYSTEM Sub-Section 04 (CARBURETORS)

DISASSEMBLY AND INSPECTION

Inspect parts for corrosion damage (shaft, throttle plate, spring, screw, check valve housing, etc

1, Needle Valve

Inspect needle valve tip for grooved conditionIf worn, needle and seat must be replaced as matched set

2, Low Speed Screw

Check tip for grooved conditionReplace if necessary

3, Diaphragm

F07F03A

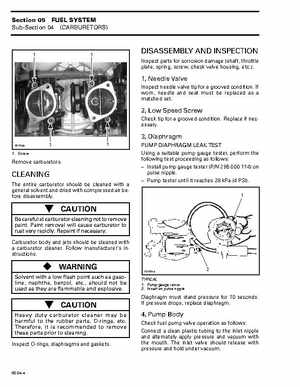

Remove carburetors

CLEANING

The entire carburetor should be cleaned with general solvent and dried with compressed air before disassembly

PUMP DIAPHRAGM LEAK TEST Using suitable pump gauge tester, perform the following test proceeding as follows: Install pump gauge tester (PN 295 000 114) on pulse nipple Pump tester until it reaches 28 kPa (4 PSI)1