Bombardier SeaDoo 1997 factory shop manual, Page 75Get this manual

Section 03 ENGINE Sub-Section 06 (BOTTOM END)

INSPECTION

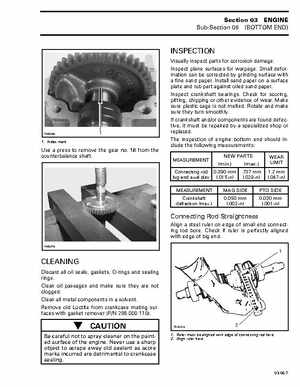

Visually inspect parts for corrosion damageInspect plane surfaces for warpageSmall deformation can be corrected by grinding surface with fine sand paperInstall sand paper on surface plate and rub part against oiled sand paperInspect crankshaft bearingsCheck for scoring, pitting, chipping or other evidence of wearMake sure plastic cage is not meltedRotate and make sure they turn smoothlyIf crankshaft andor components are found defective, it must be repaired by specialized shop or replacedThe inspection of engine bottom end should include the following measurements:

MEASUREMENT NEW PARTS (min (max .737 mm (.029 in) WEAR LIMIT 1.2 mm (.047 in)

F00D0SA

1Index mark

Use press to remove the gear no18 from the counterbalance shaft

Connecting rod 0.390 mm big end axial play (.015 in) MEASUREMENT Crankshaft deflection (max