Bombardier SeaDoo 1992 factory shop manual, Page 191Get this manual

Section 08 PROPIULSION AND DlRIVE SYSTEMS Sub-section 01 (PROPULSION AND DRIVE SYSTEMS)

Brush andclean impeller shaft threads and impeller splines with Loctite Safety solvent 755293 800 0191 or equivalentFree threads and splines from any residueAllow solvent to dry thoroughly

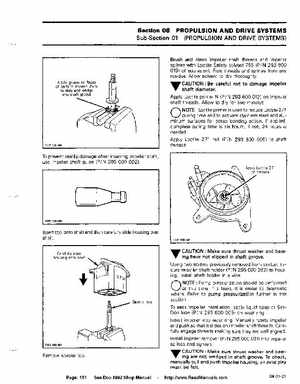

Apply grease on faces of parts to prevent them to slide and wedge into shaftgroove

CAUTIONBe careful not to damage impeller shaft diameterApply Loctite primer293 600 012) on impeller shaft threadsAllow to dry for two minutesNOTELoctite primer is used to reduce Loctite 271 curing time and to activate stainless steel and aluminum surfaces for better bonding action If applied, complete curing time is six hours,if not, 24 hours is neededApply Loctite 271 red 293 800 0051 to shaft threads

To prevent seal lllip damage when inserting impeller shaft, use impeller shaft guide295 000 002)-

Insert tool onto shaft end then carefully slide housing over shaftCarefully insert housing onto shaft