Bombardier SeaDoo 1992 factory shop manual, Page 190Get this manual

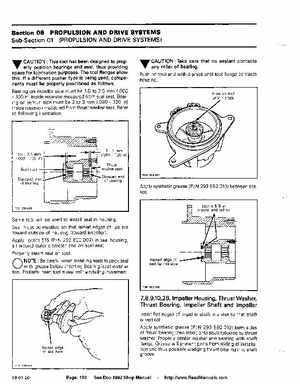

Section 08 PROPULSION AN1DDRIVE SYSTEMS Sub-section 01 (PROPULSION AND DRIVE )- CAUTIONThis tool has been designed properly position bearings and seal, thus providing space for lubrication pulrposesThe tool flanges alllow thisIf different pusher type is being used, components must be properly positioned as followsBearing on impeller side must be 1.5 to 2.5 mm t.060

CAUTIONTake care that no sealantcontacts any roller of bearingPush on tool end with press until tool flange contacts housingPush on tool until it stops

- 100 in) inside reservoir measured from seal seatBearing on ventun side must be to mm (.080.I20in1

inside reservoir measured from thrust washer seatRefer to following illustration

2-3mm120 ml

Thrust washer seat

Stamped end of bearing

Apply syntlhetic grease (PIN 293 550 010) between seal lipsLoctite 515 all around and behind

Same tool will be used to install seal in housingSeal must be installed so tlhat raised edges of llips are toward outside of housing (toward impeller) Apply Loctite 515 (PIN 293 800 007)in seal housing, all around outer diameter and on seal seat Properly insert seal on tool