Bombardier SeaDoo 1992 factory shop manual, Page 55Get this manual

Section 03 ENGINE Sub-section 03 (TOP END)

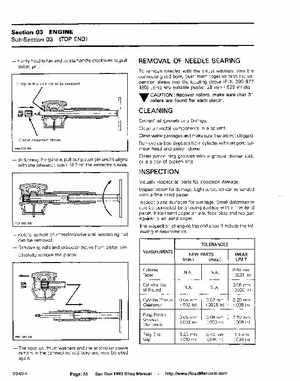

- Firmly hold puller and rotate handle clockwise to pull

piston pin

REMOVAL OF NEEDLE BEARING

To remove needles with the thrust washers from the connecting rod bore, push them together with the expansion sleeve into the locating sleeve 290 877 1801 using any suitable pusher 21 mlm826 in) dia

Clrclip at this side not to be removed

CAUTIONRecover rollers, make sure that 31 rollers are found tor each piston

Discard all gaskets and O-rings Clean all metal components in solvent Clean water passages and make sure thley are not cloggedGrease expansion sleeve

Remove carbon deposits from cylinder exhaust port, cylunder head and piston domeClean piston ring grooves with groove cleaner tool, or piece of broken ringl

- By turning the spindle, pull out piston pin until it aligns

with the reference mark 587 on the extractor sleeve-

INSPECTION

Visually inspect all parts for corrosion damage Inspect piston for damageLight scratches can be sanded with fine sand paper Inspect plane surfaces for warpage Small deformation can be corrected by grinding surface with fine sand paperInstall sand paper on surface plate and rub part against oiled sand paperThe inspection of engine top end should include the following measurements