1999 Polaris SLH, SLTH, SLX, SLTX, PRO785 Factory Service Manual, Page 255Get this manual

FINAL DRIVEJET PUMPBILGE SYSTEM

Pump To Hull Alignment

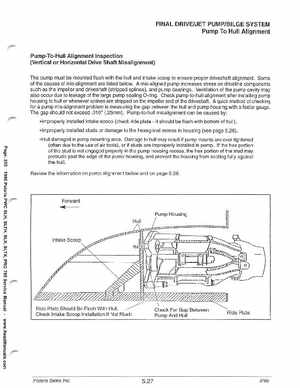

Pump-To-Hull Alignment Inspection (Vertical or Horizontal Drive Shaft Mi salignment)

The pump must be mounted flush with the hull and intake scoop to ensure proper driveshaft alignmentSome of the causes of mis-alignment are listed belowA mis-aligned pump increases stress on driveline components such as the impeller and driveshaft (stripped splines), and pump bearingsVentilation of the pump cavity may also occur due to leakage of the large pump sealing O-ringCheck pump-to-hull alignment after installing pump housing to hull or whenever splines are stripped on the impeller end of the driveshaftA quick method of checking for pump mis-alignment problem is measuring the gap between the hull and pump housing with feeler gaugeThe gap should not exceed .010" (.25mm) Pump-to-hull misalignment can be caused by:Improperly installed intake scoop (check ride plateit should be flush with bottom of hull)Improperly installed studs or damage to the hexagonal recess in housing (see page 5.28)Hull damaged in pump mounting areaDamage to hull may result if pump mounts are over-tightened (often due to the use of air tools), or if studs are improperly installed in pumpIf the hex portion of the stud is not engaged properly in the pump housing recessthe hex portion of the stud may protrude past the edge of the pump housing, and prevent the housing from seating fully against the hullReview the information on pump alignment below and on page 5.28