1999 Polaris SLH, SLTH, SLX, SLTX, PRO785 Factory Service Manual, Page 175Get this manual

ENGINECOOLING DisassemblynnspectionPolaris Engines

Crankshaft Main Bearing Inspection

1 Clean crankshaft thoroughly and oil main and connecting rod bearings with Polaris Premium cycle engine oilCarefully check each main bearing on the shaft

NOTE: Due to extremely close tolerances, the bearings

must be inspected visually, and by feelLook for signs of discoloration, scoring or gallingTurn the outer race of each bearingThe bearings should turn smoothly and quietlyThe inner race of each bearing should fit tightly on the crankshaftThe outer race should be firm with minimal side to side movement and no detectable up and down movementReplace any loose or rough bearings"C

Connecting Rod (Big End) Side Clearance

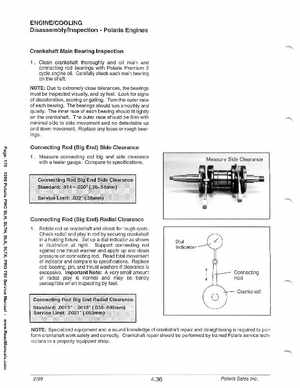

1 Measure connecting rod big end side clearance with feeler gaugeCompare to specifications

Measure Side Clearance

Connecting Rod (Big End) Radial Clearance

1Rotate rod on crankshaft and check for rough spotsCheck radial end play in rod by securing crankshaft in holding fixtureSet up dial indicator as shown in illustration at rightSupport connecting rod against one thrust washer and apply up and down pressure on connecting rodRead total movement of indicator and compare to specificationsReplace rod, bearing, pin, and thrust washers if clearance is excessiveImportant Note: vel}' small amount of radial play is normal and may be barely perceptible when inspecting by feel