1999 Polaris SLH, SLTH, SLX, SLTX, PRO785 Factory Service Manual, Page 165Get this manual

ENGINECOOLING Engine RemovalPolaris Engines 15 If engine will be completely disassembledremove drive coupler from crankshaft before loosening (4) engine mount nuts16 Remove PTO spark plugFind Top Dead Center of this piston17 Turn coupler clockwise (as viewed from rear of craft) until piston is approximately 1" (25.4 mm) before top dead centerNOTE: Estimate piston position using screwdriver or similar probe through plug hole18 Remove screwdriver or probe and insert approximately foot (30 cm) of 516" (8mm) nylon rope through spark plug holeUsing coupler tool or large wrench on flats of coupler, turn crankshaft counter clockwise until rope is trapped between piston and cylinder head With crankshaft locked in position, remove coupler by turning counter clockwise (as viewed from the rear)

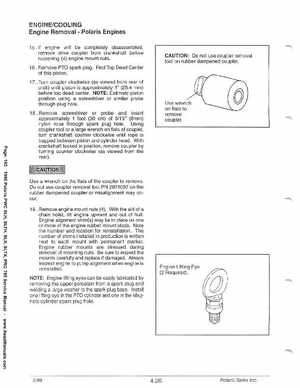

CAUTION: Do not use couple removal tool on rubber dampened coupler

Use wrench on flats to remove coupler

Use wrench on the flats of the coupler to removeDo not use coupler removal tool PN 2871037 on the rubber dampened coupler or misalignment may occur19 Remove engine mount nuts (4)With the aid of chain hoist, lift engine upward and out of hullEngine alignment shim(s) may be in place on one or more of the engine rubber mount studsNote the number and location for reinstallationThe number of shims installed in production is written next to each mount with permanent markerEngine rubber mounts are stressed during removal of mounting nutsBe sure to inspect the mounts carefully and replace if damagedAlways inspect engine to pump alignment when engine is reinstalledNOTE: Engine lifting eyes can be easily fabricated by removing the upper porcelain from spark plug and welding large washer to the spark plug baseInstall one lifting eye in the PTO cylinder and one in the Magneto cylinder spark plug hole