Suzuki outboard motors 1988 2003 repair manual., Page 331Get this manual

TRIM AND TILT 9-5 7Release the tilt lock arm and allow the motor to fall to the full down position slowly8Repeat the last three steps until no more air bubbles are seen in the line between the oil tank and the external reservoir9Place the motor in the full tilt position (from serial613245) or the full down position (up to serial613244) and remove the adapter10Add fluid until the level reaches the bottom of the oil filler hole11Tighten the filler plug to 2-3 ftIbs(3-5 Nm)12Raise and lower the motor 5-6 times using the power tilt switch4Tilt down pressure should be 1850-2420 psi (13000-17000 kPa)5If the pressure reading does not remain steady or does not reach spec! fied pressure, the pump and valve body may be faulty After the following test have been performed, check the tube connections for leaks, check the oil level in the reservoir and perform system bleedingREMOVALINSTALLATION

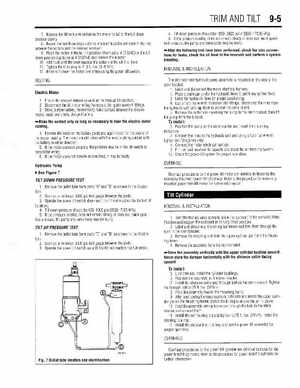

The tilt motor and hydraulic pump assembly is mounted on the side of the stern bracketI Label and disconnect the motor electrical harness2Place drain pan under the hydraulic lines to catch any spilled fluid3Label the hydraulic lines for proper positioning4Use flare nut wrench to loosen the fittingsDisconnect the lines from the hydraulic unit and cap them to prevent the entry of dirt5Remove the boltslnuts mounting the pump to the stern bracket, then lift the pump from the bracketTo install: 6Position the pump on the stern bracket and install the mounting boltslnuts7Connect the lines to the hydraulic unit and using flare nut wrench, tighten the fittings securely8Connect the motor electrical harness9Fill the fluid reservoir to capacity and bleed the air from the system10Check the power tilt system for proper operationTESTING

Electric Motor

Ensure the manual release valve is in the manual tilt position2Disconnect the tilt motor wiring harness at the quick connect fittings3Using jumper cables, momentarily make contact between the disconnected leads and fully charged battery -¥Mak the contact only as long as necessary to hear the electric motor rotatingReverse the leads on the battery posts and again listen for the sound of the motor rotating The motor should rotate with the leads making contact with the battery in either direction If the motor operates properly, the problem may be in the tilt switch or associated wiring If the motor does not operate as specified, it may be faulty