Suzuki outboard motors 1988 2003 repair manual., Page 288Get this manual

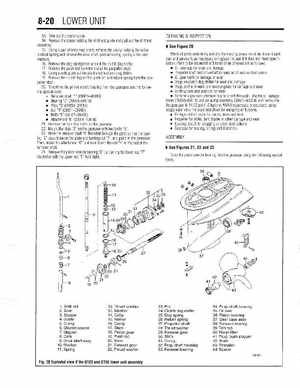

8-20 LOWER UNIT 13Take out the pinion shim14Remove the screw holding the shift rod guide and pull out the shift rod assembly15Using pair of snap ring pliers, remove the circlip holding the collar preload spring and remove the drive shaft, preload spring, spring collar and washers16Remove the dog spring from around the clutch dog shifter17Remove the push rod from the end of the propeller shaft18Using drift, push out the pin from the clutch dog shifter19Remove the clutch dog shifter, push pin and return spring from the propeller shaft20To remove the pinion needle bearing from the gearcase, use the following special tools: Remover shaft "1" (09951-49910) Bearing "2" (09951-69910) Plate(09951-39914) Nut "4" (09951-29910) Bolts "5" (01107-08408) Attachment(09951-19610) 21Remove the four stud bolts on the gearcase22Mount the plate "3" on the gearcase with two bolts "5"23Have the remover shaft "1" threaded through the plate so that the bearing "2" stays between the plate and turning nut "7", and put it in the gearcaseThen, install the attachment "6" and hold it with the nutat the end of the remover shaft24Remove the pinion needle bearingby turning the lower nut "7" clockwise with the upper nut "9" held tightCLEANINGINSPECTION

ISee Figure 20

Wash all parts completely and dry them using compressed airInspect each part and service it, as necessary, or replace the part if it does not meet specificationParts to be inspected and items to be checked are as follows: All bearings for wear and damage Propeller shaft and driveshaft for wear at oil seal contact points All gear teeth for damage or wear Dogs on clutch dog shifter for wear and damage Dogs on the forward and reverse gears for damage and wear Shifting cam and pushrod for wear Perform gearcase pressure test to check the sealsUse the oil leakage tester (09950-69511) and air pump assembly (09821-00004) and pressurize the gearcase to 14.22 psi (1.0 kglcm)With the gearcase pressurized, spray soapy water onto the seals and check for escaping air bubblesO-rings and oil seals for cracks, tears and wear Propeller for nicks, bent blades or other damage and wear Cooling circuit for clogging or other obstructions Gearcase for rusting, pitting and distortionASSEMBLY