Suzuki outboard motors 1988 2003 repair manual., Page 246Get this manual

7-34 POWERHEAD tools and abilitiesYou will have to decide for yourself the depth of involvement you desire in powerhead repair or rebuildTOOLS

The tools required for powerhead overhaul or parts replacement will depend on the depth of your involvementWith few exceptions, they will be the tools found in an average do it yourselfer's tool kitMore in-depth work will require some or all of the following: dial indicator (reading in thousandths) mounted on universal base Micrometers and telescope gauges Jaw and screw-type pullers Scraper Ring groove cleaner Piston ring expander and compressor Ridge reamer Cylinder hone or glaze breaker Plastigagea Powerhead stand The use of most of these tools is illustrated in this sectionMany can be rented for one-time use from local parts store or tool supply houseOccasionally, the use of special tools is necessarySee the information on Special Tools and the Safety Notice in the front of this book before substituting another toolRemove any plugs or pressed-in bearings and carefully wash and degrease all of the powerhead components including the fasteners and boltsSmall parts should be placed in metal basket and allowed to soakUse pipe cleaner type brushes and clean all passageways in the componentsUse ring expander to remove the rings from the pistonsClean the piston ring grooves with ring groove cleaner or piece of broken ringScrape the carbon off of the top of the pistonYou should never use wire brush on the pistonsAfter preparing all of the piston assemblies in this manner, wash and degrease them againREPAIRING DAMAGED THREADS

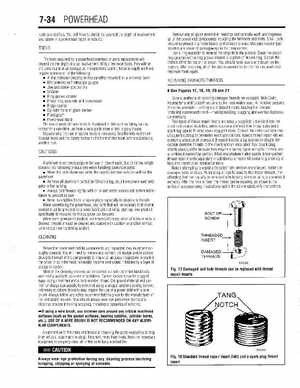

ISee Figures 17, 18, 19, 20 and 21

Several methods of repairing damaged threads are availableHeli-Coila, Keensertsa and Microdota are among the most widely usedAll involve basically the same principle-drilling out stripped threads, tapping the hole and installing prewound insert-making welding, plugging and oversize fasteners unnecessaryTwo types of thread repair inserts are usually supplied: standard type for most inch coarse, inch fine, metric course and metric fine thread sizes and spark lug type to fit most spark plug port sizesConsult the individual tool manufacturer's catalog to determine exact applicationsTypical thread repair kits will contain selection of prewound threaded inserts, tap (corresponding to the outside diameter threads of the insert) and an installation toolSpark plug inserts usually differ because they require tap equipped with pilot threads and combined reamerltap sectionMost manufacturers also supply blister-packed thread repair inserts separately in addition to master kit containing variety of taps and inserts plus installation toolsBefore attempting to repair threaded hole, remove any snapped, broken or damaged bolts or studsPenetrating oil can be used to free frozen threadsThe offending item can usually be removed with locking pliers or using screwlstud extractorAfter the hole is clear, the thread can be repaired, as shown in the series of accompanying illustrations and in the kit manufacturer's instructions