Suzuki outboard motors 1988 2003 repair manual., Page 158Get this manual

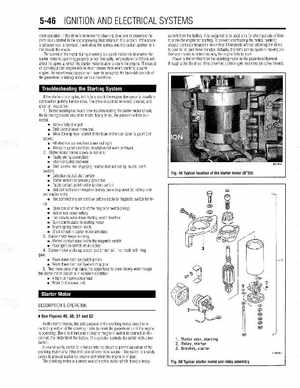

5-46 IGNITION AND ELECTRICAL SYSTEMS cient operationIf the drive is removed for cleaning, take care to assemble the parts as illustrated in the accompanying illustrations in this sectionIf the screw shaft assembly is reversed, it will strike the splines and the rubber cushion will not absorb the shockThe sound of the motor during cranking is good indication of whether the starter motor is operating properly or notNaturally, temperature conditions will affect the speed at which the starter motor is able to crank the engineThe speed of cranking cold engine will be much slower than when cranking warm engineAn experienced operator will learn to recognize the favorable sounds of the powerhead cranking under various conditionscurrent from the batteryIt is designed to be used only for short periods of time to crank the engine for startingTo prevent overheating the motor, cranking should not be continued for more than 30-seconds without allowing the motor to cool for at least three minutesActually, this time can be spent in making preliminary checks to determine why the engine fails to startPower is transmitted from the cranking motor to the powerhead flywheel through Bendix driveThis drive has pinion gear mounted on screw threadsIf the starter motor spins, but fails to crank the engine, the cause is usually corroded or gummy Bendix driveThe drive should be removed, cleaned, and given an inspection1Before wasting too much time troubleshooting the starter motor circuit, the following checks should be madeMany times, the problem will be correctedBattery fully chargedShift control lever in neutralMain 20-amp fuse located at the base of the fuse cover is good (not blown)All electrical connections clean and tightWiring in good condition, insulation not worn or frayed2Starter motor cranks slowly or not at allFaulty wiring connection Short-circuited lead wire Shift control not engaging neutral (not activating neutral start switch) Defective neutral start switch Starter motor not properly grounded Faulty contact point inside ignition switch Bad connections on negative battery cable to ground (at battery side and engine side) Bad connections on positive battery cable to magnetic switch terminal Open circuit in the coil of the magnetic switch (relay) Bad or run-down battery Excessively worn down starting motor brushes Burnt commutator in starting motor Brush spring tension slack Short circuit in starter motor armature 3Starter motor keeps runningMelted contact plate inside the magnetic switch Poor ignition switch return action 4Starter motor picks up speed, put pinion will not mesh with ring gear Worn down teeth on clutch pinion Worn down teeth offlywheel rlng gear Two more areas may cause the powerhead to crank slowly even though the starter motor circuit is in excellent condition tight or frozen powerhead Water in the lower unit