Suzuki outboard motors 1988 2003 repair manual., Page 68Get this manual

4-6 FUEL SYSTEM DUAL-THROAT CARBURETORS

The carburetor systems on V4 and V6 engines require careful cleaning and adjustment if problems occurThese carburetors are not difficult to understandI carburetors operate on the same principlesFor best results, trace and analyze one circuit at timeBeginning in 1996, all Saltwater series 90 degree engines have an additional jet in the carburetorThis pull over or enrichment jet improves mid-range response while maintaining fuel economyAdditional enrichment is necessary to start cold engineFuellair mixes to not want to vaporize in cold engineIn order to get little fuel to vaporize, lot of fuel is dumped into the engineOn most V4 and V6 engines, choke plate is used for cold startsThis plate restricts air entering the engine and increases the fuellair ratioThe enrichment system on the 90-degree 225 hp engines is controlled by microprocessorTemperature and throttle position are monitored and enrichment is automaticA pair of injectors with different diameters are used to provide enrichmentProper procedure involves: 1Shutting off the fuel supply at the tank2Disconnecting the fuel line at the tank3Operating the engine until it begins to run rough, then stopping the engine, which will leave some fuelloil mixture inside4Removing and draining the carburetorBy disconnecting the fuel supply, all small passages are cleared of fuel even though some fuel is left in the carburetorA light oil should be put in the combustion chamber as instructed in the owner's manualOn some model carburetors the high-speed jet plug can be removed to drain the fuel from the carburetorFor short periods of storage, simply running the carburetor dry may help prevent severe gum and varnish from forming in the carburetorThis is especially true during hot weatherISee Figures thru 8

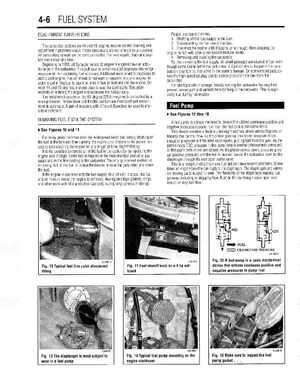

fuel pump is basic mechanical device that utilizes crankcase positive and negative pressures to pump fuel from the fuel tank to the carburetorsThis device contains flexible diaphragm and two check valves (flappers or fingers) that control flowAs the piston goes up, crankcase pressure drops (negative pressure) and the inlet valve opens, pulling fuel from the tankAs the piston nears TDC, pressure in the pump area is neutral (atmospheric pressure)At this point both valves are closedAs the piston comes down, pressure goes up (positive pressure) and the fuel is pushed toward the carburetor bowl by the diaphragm through the now open outlet valveThis is reliable method to move fuel but can have several problemsSometimes an engine backfire can rupture the diaphragmThe diaphragm and valves are moving parts subject to wearThe flexibility of the diaphragm material can go away, reducing or stopping flowRust or dirt can hang valve open and reduce or stop fuel flowREMOVING FUEL FROM THE SYSTEM