Suzuki outboard motors 1988 2003 repair manual., Page 19Get this manual

MAINTENANCE 3-3 The system is powered by the crankshaft which drives gear in the pump, creating oil pressureAs the throttle lever is advanced to increase engine speed, the linkage arm also moves, opening valve that allows more oil to flow into the oil pumpMost mechanical-injection systems incorporate low-oil warning alarms that are also connected to an engine overheating sensorAlso, these systems may have built-in speed limiterThis sub-system is designed to reduce engine speed automatically when oil problems occurThis important feature goes long way toward preventing severe engine damage in the event of an oil injection problemThe procedure for filling these systems is simpleOn each powerhead there is an auxiliary oil reservoir which holds the 2-stroke oilSimply fill the oil take to the proper capacityIt is highly advisable to carry several spare bottles of 2-stroke oil with you onboardFor more information on the oil injection system refer to the "Lubrication and Cooling" section of this manualFigures and See

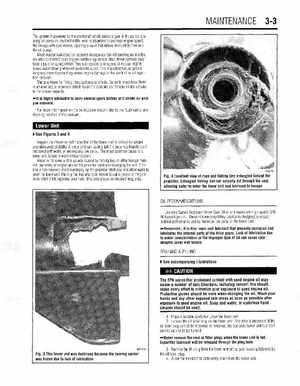

Regular maintenance and inspection of the lower unit is critical for proper operation and reliability lower unit can quickly fail if it becomes heavily contammated with water, or excessively low on oil The most common cause of lower unit failure is water contamination Water in the lower unit is usually caused by fishing line, or other foreign material, becoming entangled around the propeller shaft and damaging the seal If the shaft seal and allow water to line is not removed it will eventuallv cut the oroeller enter the lower unit: Fishing line has also been known to cut groove in the propeller shaft if left neglected over timeThis area should be checked frequently04703P28

Fig4 Excellent view of rope and fishing line entangled behind the propellerEntangled fishing line can actually cut through the seal, allowin water to enter the lower unit and lubricant to escape