Suzuki 2-15HP outboard motors Service Manual, Page 12Get this manual

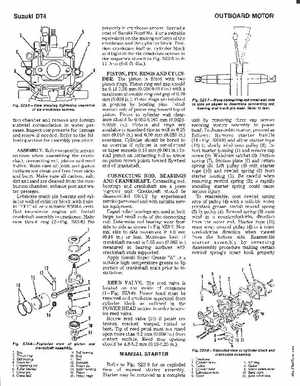

Suzuki DT4 properly in crankcase grooveSpread coat of Suzuki Bond No.4 or suitable equivalent on the mating surfaces of the crankcase and the cylinder blockPosition crankcase half on cylinder block and tighten the six crankcase screws in the sequence shown in FigSZ3-5 to 812 N'm (6-8 ftIbsPISTON, PIN, RINGS AND CYLINDERThe piston is fitted with two piston ringsPiston ring end gap should be 0.15-0.35 mm (0.006-0.014 in with maximum allowable ring end gap of 0.70 mm (0.028 inPiston rings are retained in position by locating pinsInstall marked side of piston ring toward top of pistonPiston to cylinder wall clearance should be 0.052-0.067 mm (0.00200.0026 inPistons and rings are available in standard size as well as 0.25 mm (0.010 in and 0.50 mm (0.020 in oversizesCylinder should be bored to an oversize if cylinder is out-of-round or taper exceeds 0.10 mm (0.004 in Install piston on connecting rod so arrow on piston crown points toward flywheel end of crankshaftCONNECTING ROD, BEARINGS AND CRANKSHAFTConnecting rod, bearings and crankshaft are press together unitCrankshaft should be disassembled ONLY by experienced service personnel and with suitable service equipmentCaged roller bearings are used at both large and small ends of the connecting rodDetermine rod bearing wear from side to side as shown in Fig SZ3-7Normal side to side movement is 4.0 mm (0.16 in or lessMaximum limit of crankshaft runout is 0.05 mm (0.002 in measured at bearing surfaces with crankshaft ends supportedApply Suzuki Super Grease "A" or suitable high temperature grease to lip portion of crankshaft seals prior to installationREED VALVEThe reed valve is located on the inside of crankcase (I-FigSZ3-8)Power head must be removed and crankcase separated from cylinder block as outlined in the POWER HEAD section in order to service reed valveRenew reed valve (10) if petals are broken, cracked, warped, rusted or bentTip of reed petal must not stand open more than 0.2 mm (0.008 in from contact surfaceReed stop opening should be 4.8-5.2 mm (0.190.20 in