Mercury Mariner Outboard 225 3 Litre Service Manual 1994, Page 142Get this manual

addition to bearingsAfter cleaning, bores should be swabbed several times with engine oil and clean cloththen wiped with cleandry cloth Cylinders should not be cleaned with kerosene or gasoline Clean remainder of cylinder block to remove excess material spread du ring honing operation23Hone all cylinder walls just enough to de-glaze wallsMeasure cylinder bore diameter (with snap gauge micrometer) of each cylinder, as shown belowCheck for tapered, out-of-round (egg-shaped) and oversize bore Pistons and Piston Rings

IMPORTANT: If engine was submerged while engine was running, piston pin andor connecting rod may be bentIf piston pin is bent, piston must be replaced(Piston pins are not sold separately because of matched fit into piston If piston pin is bent, connecting rod must be checked for straightness (refer toConnecting Rods," following, for checking straightness)12Inspect pistons for scoring and excessive piston skirt wearCheck tightness of piston ring locating pinsLocating pins must be tight

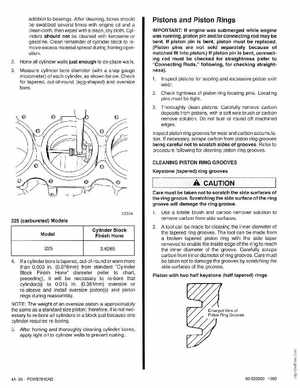

3Thoroughly clean pistonsCarefu lly remove carbon deposits from pistons, with soft wire brush or carbon remove solution Do not burr or round off machined edgesInspect piston ring grooves for wear and carbon accumulationIf necessary, scrape carbon from piston dng grooves being careful not to scratch sides of groovesRefer to procedure following for cleani ng piston ring groovesCLEANING PISTON RING GROOVES Keystone (tapered) ring grooves