Mercury Mariner 200, 225 Optimax Outboards Service Manual, 90-855348, Page 239Get this manual

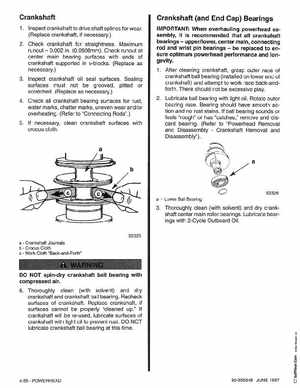

Crankshaft 1Inspect crankshaft to drive shaft splines for wear(Replace crankshaft, if necessary 2Check crankshaft for straightnessMaximum runout0.002 in(0.0508mm)Check runout at center main bearing surfaces with ends of crankshaft supported in v-blocks(Replace as necessary) 3Inspect crankshaft oil seal surfacesSealing surfaces must not be grooved, pitted or scratched(Replace as necessary 4Check all crankshaft bearing surfaces for rust, water marks, chatter marks, uneven wear andor overheating(Refer to "Connecting Rods" 5If necessary, clean crankshaft surfaces with crocus cloth

Crankshaft (and End Cap) Bearings

IMPORTANT: When overhauling powerhead assembly, it is recommended that all crankshaft bearingsupperllower, center main, connecting rod and wrist pin bearingsbe replaced to ensure optimum powerhead performance and longevity1After cleaning crankshaft, grasp outer race of crankshaft ball bearing (installed on lower end of crankshaft) and attempt to work race back-andforthThere should not be excessive play2Lubricate ball bearing with light oilRotate outer bearing raceBearing should have smooth action and no rust stainsIf ball bearing sounds or feels "rough" or has "catches," remove and discard bearing(Refer to "Powerhead Removal and DisassemblyCrankshaft Removal and Disassembly")