Mercury 35/40HP 2 Cylinder Outboards Service Manual PN 90-42794--1, Page 147Get this manual

4Apply Loctite Grade "A" onto threads of new pinion nut and install components5Clamp drive shaft in soft jawed vise and torque pinion nut to 50 lbft(65 Nm) a d

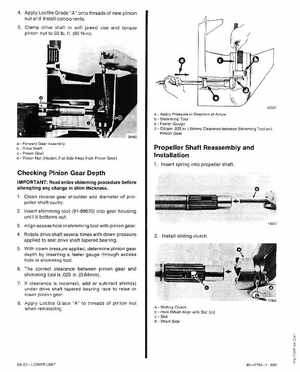

Apply Pressure in Direction of Arrow Shimming Tool Feeler Gauge Obtain .025 in (.64mm) Clearance between Shimm ing Tool and Pinion Gear

Forward Gear Assembly Drive Shaft Pinion Gear Pinion Nut (HiddenFlat Side Away from Pinion Gear)

Propeller Shaft Reassembly and Installation

1Insert spring into propeller shaft

Checking Pinion Gear Depth

IMPORTANT: Read entire shimming procedure before attempting any change in shim thickness

1Clean reverse gear shoulder and diameter of propeller shaft cavity2Insert sh imming tool (91-89670) into gear housing until it bottoms out3Align access hole in shimming tool with pinion gear4Rotate drive shaft several times with down pressure applied to seat drive shaft tapered bearing5With down pressure applied, determine pinion gear depth by inserting feeler gauge through access hole in shimming tool6The correct clearance between pinion gear and shimming tool is .025 in (0.64mm) 7If clearance is incorrect, add or subtract shim(s) under drive shaft tapered bearing race to raise or lower pinion gear8Apply Loctite Grade "A" to threads of pinion nut when reinstallinga d