1984-1986 Mercury Force 4HP Outboards Service Manual, Page 47Get this manual

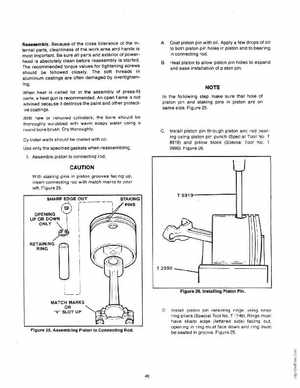

RuemblyBecause of the close tolerance of the inlernal parts, cleanliness of Ihe work area and hands is most importantBe sure all parts and exterior of powerhead is absolutely clean before reassembly is startedThe recommended torque values for tightening screws should be followed closelyThe soft threads aluminum castings are often damaged by overtightening When heat is called for in the assembly of press-fit parts, heat gun is recommendedAn open flame is not advised because it destroys the paint and other protective coatings With new or rehoned cylinders, the bore shou ld be thoroughly scrubbed with warm soapy water usi ng round bore brush Dry thoroughlyCyl inder walls should be coated with oilUse on ly the specified gaskets when reassemblingCoat piston pin with oilApply few drops of oil to both piston pin holes in piston and 10 beari ng connecting rod Heat piston to allow piston pin hates to expand and ease installation of piston pinNOTE In the following step make sure that hole of piston pin and staking pins in piston are on same side Figure 25Install piston pin through piston and rod bearing using piston pin punch (Special Tool NoT 8919) and pillow block (Special Tool NoT 2990) Figure 26