Johnson Evinrude Outboard Motors 1956-1970 1.5-40hp repair manual., Page 323Get this manual

ELECTROMA TIC SHIFT CLEANING AND INSPECTING

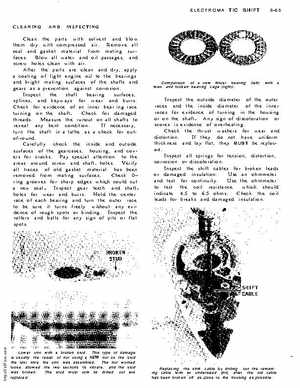

Clean the parts with solvent and blow them dry with compressed airRemove all seal and gasket material from mating surfacesBlow all water and oil passages, and screw holes clean with airAfter the parts are clean and dry, apply coating of light engine oil to the bearings and bright mating surfaces of the shafts and gears as prevention against corrosionInspect the shaft bearing surfaces, splines, and keyways for wear and burrsCheck for evidence of an inner bear ing race turning on the shaftCheck for damaged threadsMeasure the runout on all shafts to reveal any bent conditionIf necessary, turn the shaft in lathe as check for outof-roundCarefully check the inside and outside surfaces of the gearcases, housing, and covers for cracksPay special attention to the areas around screw and shaft holesVerify all traces of old gasket material has been removed from mating surfacesCheck 0ring grooves for sharp edges which could cut new sealInspect gear teeth and shaft holes for wear and burrsHold the center race of each bearing and turn the outer race to be sure it turns freely without any evidence of rough spots or bindingInspect the rollers and balls for any sign of pits or flat spots