Johnson Evinrude Outboard Motors 1956-1970 1.5-40hp repair manual., Page 218Get this manual

ELECTRICAL

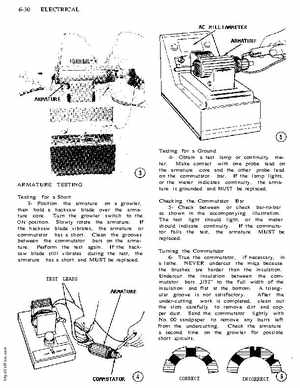

ARMATURE TESTING Testing for Short 3- Position the armature on growler, then hold hacksaw blade over the armature coreTurn the growler switch to the ON positionSlowly rotate the armatureIf the hacksaw blade vibrates, the armature or commutator has shortClean the grooves between the commutator bars on the armaturePerform the test againIf the hacksaw blade still vibrates during the test, the armature has short and MUST be replaced

Testing for Ground 4- Obtain test lamp or continuity meterMake contact with one probe lead on the armature core and the other probe lead on the commutator barIf the lamp lights, or the meter indicates continuity, the armature is grounded and MUST be replacedChecking the Commutator Bar 5- Check between or check bar-to-bar as shown in the accompanying illustrationThe test light should light, or the meter should indicate continuityIf the commutator fails the test, the armature MUST be replacedTurning the Commutator 6- True the commutator, if necessary, in latheNEVER undercut the mica because the brushes are harder than the insulationUndercut the insulation between the commutator bars 132" to the full width of the insulation and flat at the bottomA triangular groove is not satisfactoryAfter the under-cutting work is completed, clean out the slots carefully to remove dirt and copper dustSand the commutator lightly with No00 sandpaper to remove any burrs left from the undercuttingCheck the armature second time on the growler for possible short circuits