Johnson Evinrude Outboard Motors 1956-1970 1.5-40hp repair manual., Page 135Get this manual

TYPE III CARBURETOR

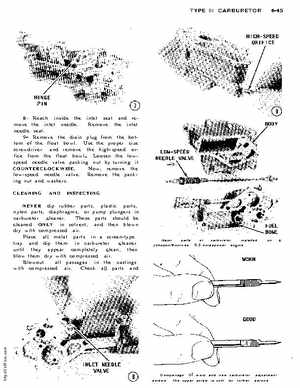

8- Reach inside the inlet seat and remove the inlet needleRemove the inlet needle seat9- Remove the drain plug from the bottom of the float bowlUse the proper size screwdriver and remove the high-speed orfice from the float bowlLoosen the lowspeed needle valve packing nut by turning it COUNTERCLOCKWISENow, remove the low-speed needle valveRemove the packing nut and washersCLEANING AND INSPECTING

NEVER dip rubber parts, plastic parts, nylon parts, diaphragms, or pump plungers in carburetor cleanerThese parts should be cleaned ONLY in solvent, and then blown dry with compressed airPlace all metal parts in screen-type tray and dip them in carburetor cleaner until they appear completely clean, then blow them dry with compressed airBlowout all passages in the castings with compressed airCheck all parts and