2004 SR Johnson 2-stroke 40, 50HP Service Manual, Page 213Get this manual

MIDSECTION CLEANING AND INSPECTION

CLEANING AND INSPECTION

General

Exhaust Housing

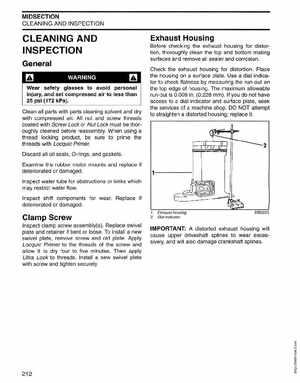

Before checking the exhaust housing for distortion, thoroughly clean the top and bottom mating surfaces and remove all sealer and corrosion

WARNING

Wear safety glasses to avoid personal injury, and set compressed air to less than 25 psi (172 kPa)Clean all parts with parts cleaning solvent and dry with compressed airAll nut and screw threads coated with Screw Lock or Nut Lock must be thoroughly cleaned before reassemblyWhen using thread locking product, be sure to prime the threads with Locquic PrimerDiscard all oil seals, O-rings, and gasketsExamine the rubber motor mounts and replace if deteriorated or damagedInspect water tube for obstructions or kinks which may restrict water flowInspect shift components for wearReplace if deteriorated or damaged

Check the exhaust housing for distortionPlace the housing on surface plateUse dial indicator to check flatness by measuring the run-out on the top edge of housingThe maximum allowable run-out is 0.009 in(0.228 mm)If you do not have access to dial indicator and surface plate, seek the services of machine shopDO NOT attempt to straighten distorted housing; replace it