1999 "EE" Evinrude 70HP 4-Stroke Service Manual, P/N 787023, Page 127Get this manual

In 0.6 in(15 mm)

DRC7673

7The difference between your measurements and standard bore dimension is cylinder oversizeRefer to Engine Component Specifications, this section, for dimensionsThe cylinder must not be oversize by more than 0.004 in (0,10 mml

INote If any cylinder is outside these tolerances, it must be bored

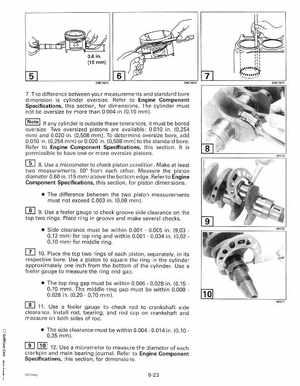

oversizeTwo oversized pistons are available: 0.010 in(0,254 mml and 0.020 in(0,508 mmlTo determine oversize bore, add 0.010 in (0,254 mml or 0.020 in(0,508 mml to the standard boreRefer to Engine Component Specifications, this sectionIt is permissible to have one or more oversize pistons[] 8Use micrometer to check piston condition Make at least two measurements, 90 from each otherMeasure the piston diameter 0.60 in(15 mml above the bottom edgeRefer to Engine Component Specifications, this section, for piston dimensions The difference between the two piston measurements must not exceed 0.003 in(0,08 mml[] 9Use feeler gauge to check groove side clearance on the top two ringsPlace ring in groove and make several checks Side clearance must be within 0.0010.005 in(9,03 0,12 mml for top ring and within 0.0010.004 in(0,02 0,10 mml for middle ring[] 10Place the top two rings of each piston, separately, in its respective boreUse piston to square the ring in the cylinder approximately one inch from the bottom of the cylinderUse feeler gauge to measure the ring end gap The top ring gap must be within 0.0060.028 in(0,15 0,70 mmlThe middle ring gap must be within 0.008 0.028 in(0,200,70 mml[] 11Use feeler gauge to check rod to crankshaft side clearanceInstall rod, bearing, and rod cap on crankshaft and measure on both sides of rod