1998 Johnson Evinrude "EC" 125C, 130, 200, 225, 250 90 deg LV Service Manual, P/N 520212, Page 319Get this manual

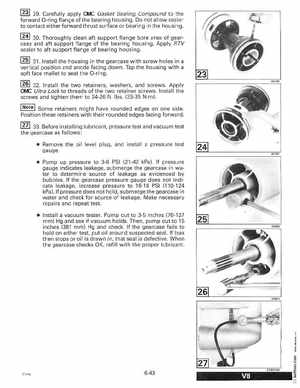

29Carefully apply OMC Gasket Sealing Compound to the forward O-ring flange of the bearing housingDo not allow sealer to contact either forward thrust surface or bearing in the housing30Thoroughly clean aft support flange bore area of gearcase and aft support flange of the bearing housingApply RTV sealer to aft support flange of bearing housing 31 Install the housing in the gearcase with screw holes in vertical position and anode facing downTap the housing with soft face mallet to seat the O-ring44190

1241 1251

32Install the two retainers, washers, and screwsApply OMC Ultra Lock to threads of the two retainer screwsInstall the screws and tighten them to 24-26 ftIbs(33-35 Nm)retainers might have rounded edges on one sidePosition these retainers with their rounded edges facing forward

INote Some 1271

33Before installing lubricant, pressure test and vacuum test the gearcase as followsRemove the oil level plug, and install pressure test gauge Pump up pressure to 3-6 PSI (21-42 kPa) If pressure gauge indicates leakage, submerge the gearcase in water to determine source of leakage as evidenced by bubblesIf the gearcase pressure gauge does not indicate leakage, increase pressure to 16-18 PSI (110-124 kPa)If pressure does not hold, submerge the gearcase in water and check for source of leakage Make necessary repairs and repeat test Install vacuum testerPump out to 3-5 inches (76-127 mm) Hg and see if vacuum holdsThen, pump out to 15 inches (381 mm) Hg and checkIf the gearcase fails to hold on either test, put oil around suspected sealIf leak then stops or oil is drawn in, that seal is defectiveWhen the gearcase checks OK, refill with the proper lubricant