1997 Johnson Evinrude "EU" 90, 105RW, 115, 150, 150W, 175 60 LV Service Manual, P/N 507268, Page 66Get this manual

Testing Procedure

Avoid accidental starting of engine while changing propellers; twist and remove all spark plug leads

I Note Some checks require that the engine be run at full throttle

under loadInstall the correct test propeller and run the engine in suitable test tank1Start engine and allow it to reach normal operating temperatureINotel Push fuel hose off fuel fittingsdon't pullIf pushing

won't separate hose and fitting, carefully cut the hose along its side and peel it back to avoid damaging the fittings

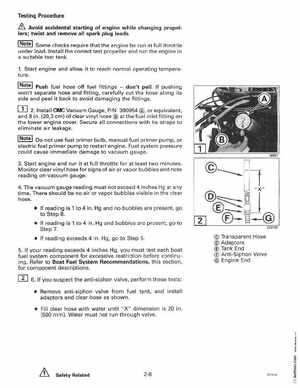

2Install OMC Vacuum Gauge, PIN 390954or equivalent, and in(20,3 cm) of clear vinyl hose at the fuel inlet fitting on the lower engine coverSecure all connections with tie straps to eliminate air leakageelectric fuel primer pump to restart engineFuel system pressure could cause immediate damage to vacuum gauge3Start engine and run it at full throttle for at least two minutesMonitor clear vinyl hose for signs of air or vapor bubbles and note reading on vacuum gauge4The vacuum gauge reading must not exceed inches Hg at any timeThere should be no air or vapor bubbles visible in the clear hose If reading is to inHg and no bubbles are present, go to Step If reading is to inHg and bubbles are present, go to Step If reading exceeds in Hg, go to Step 55If your reading exceeds inches Hg, you must test each boat fuel system component for excessive restriction before continuingRefer to Boat Fuel System Recommendations, this section, for component descriptions6If you suspect the anti-siphon valve, perform these tests: Remove anti-siphon valve from fuel tank, and install adaptors and clear hose as shown Fill clear hose with water until "X" dimension is 20 in(500 mm)Water must not run through valve