1996 Johnson Evinrude "ED" 60 LV 90, 115, 150, 150C, 175 Service Manual, P/N 507127, Page 149Get this manual

1 19l 13Inspect center main bearing and split sleeves for excess wear, nicks or scratchesReplace if necessaryi.iQl 14Inspect crankshaft rod bearings for excess wear, nicks or scratchesReplace if necessaryAssembly

Proceed slowlyMake no forced assemblies unless pressing operation is called forAll internal components must be perfectly clean and lightly coated with Johnson and Evinrude Outboard LubricantUse new wrist pin retaining rings, gaskets, seals, and a-rings during assembly

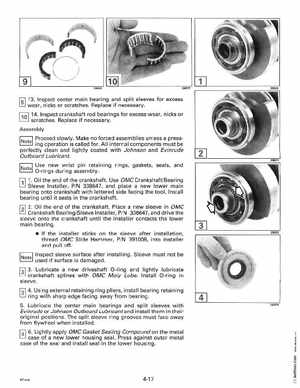

f11 1Oil the end of the crankshaftUse OMC CrankshaftBearing Sleeve Installer, PIN 338647, and place new lower main bearing onto crankshaft with lettered side facing the toolInstall bearing until it seats in the crankshaft

l=.J Crankshaft Bearingl Sleeve Installer, PI 338647, and drive the

f21 2Oil the end of the crankshaftPlace new sleeve in

sleeve onto the crankshaft until the installer contacts the lower main bearing If the installer sticks on the sleeve after installation, thread OMC Slide Hammer, PI 391008, into installer and pull offInspect sleeve surface after installing Sleeve must not be used if surface is damagedfJl 3Lubricate new driveshaft a-ring and lightly lubricate crankshaft splines with OMC Moly LubeInstall a-ring in sleevefJl 4Using external retaining ring pliers, install bearing retaining ring with sharp edge facing away from bearing 5Lubricate the center main bearings and split sleeves with Evinrude or Johnson Outboard Lubricant and install them in their original positionsThe split sleeve ring grooves must face away from flywheel when installed24399