1995 Johnson/Evinrude Outboards 40 thru 55 2-Cylinder Service Manual, Page 177Get this manual

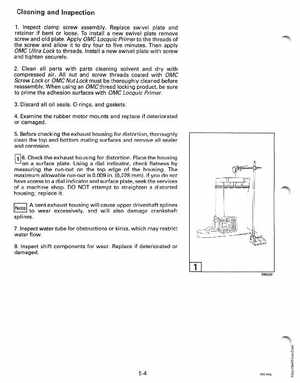

Cleaning and Inspection 1Inspect clamp screw assemblyReplace swivel plate and retainer if bent or looseTo install new swivel plate remove screw and old plateApply OMC Locquic Primer to the threads of the screw and allow it to dry four to five minutesThen apply OMC Ultra Lock to threadsInstall new swivel plate with screw and tighten securely2Clean all parts with parts cleaning solvent and dry with compressed airAll nut and screw threads coated with OMC Screw Lock or OMC Nut Lock must be thoroughly cleaned before reassemblyWhen using an OMCthread locking product, be sure to prime the adhesion surfaces with OMC Locquic Primer3Discard all oil seals, a-rings, and gaskets4Examine the rubber motor mounts and replace if deteriorated or damaged5Before checking the exhaust housing for distortion, thoroughly clean the top and bottom mating surfaces and remove all sealer and corrosion[TI 6Check the exhaust housing for distortionPlace the housing on surface plateUsing dial indicator, check flatness by measuring the run-out on the top edge of the housingThe maximum allowable run-out is 0.009 in(0,228 'mm)If you do not have access to dial indicator and surface plate, seek the services of machine shopDO NOT attempt to straighten distorted housing; replace itA bent exhaust housing will cause upper driveshaft splines to wear excessively, and will also damage crankshaft splines7Inspect water tube for obstructions or kinks, which may restrict water flow8Inspect shift components for wearReplace if deteriorated or damagedDR2223