1995 Johnson Evinrude "EO" 9.9 thru 30, 2-Cylinder Service Manual, P/N 503146, Page 312Get this manual

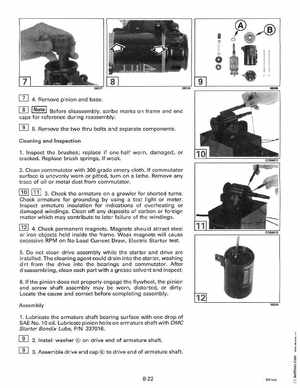

4Remove pinion and base

[]] INote Before disassembly, scribe marks on frame and end

caps for reference during reassembly[[] 5Remove the two thru bolts and separate componentsCleaning and Inspection 1Inspect the brushes; replace if one-half worn, damaged, or crackedReplace brush springs, if weak2Clean commutator with 300 grade emery clothIf commutator surface is unevenly worn or pitted, turn on latheRemove any race of oil or metal dust from commutator

3Check the armature on growler for shorted turnsCheck armature for grounding by using test light or meterInspect armature insulation for indications of overheating or damaged windingsClean off any deposits of carbon or foreign matter which may contribute to later failure of the windings4Check permanent magnetsMagnets should attract steel or iron objects held inside the frameWeak magnets will cause excessive RPM on No Load Current Draw, Electric Starter test5Do not clean drive assembly while the starter and drive are installedThe cleaning agent could drain into the starter, washing dirt from the drive into the bearings and commutatorAfter disassembling, clean each part with grease solvent and inspect6If the pinion does not properly engage the flywheel, the pinion and screw shaft assembly may be worn, distorted, or dirtyLocate the cause and correct before completing assembly