1992 Johnson Evinrude "EN" 90 deg. Cross V Service Manual, P/N 508145, Page 181Get this manual

31Rotate cylinder block so that crankcase mating flange is facing up1261 32Remove all spark plugs and push all pistons to top dead centerRemove numbered connecting rod caps and hold rods to the outside with rubber bands27 1

33 Gently lower crankshaft assembly into place Orient all crankcase seal ring gaps facing up Tap crankshaft upward with rawhide mallet to seat crankshaft and lower crankcase head Locate each center main bearing split sleeve on its dowel pin

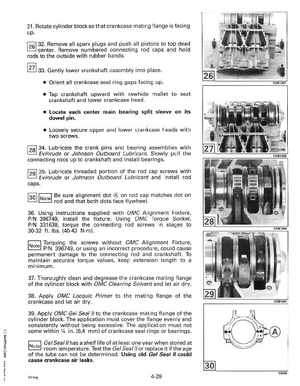

Loosely secure upper and lower crankcase heads with two screws1281 34Lubricate the crank pins and bearing assemblies with Evinrude or Johnson Outboard LubricantSlowly pull the connecting rods up to crankshaft and install bearings1291 35Lubricate threaded portion of the rod cap screws with Evinrude or Johnson Outboard Lubricant and install rod caps

Be sure alignment dot on rod cap matches dot on rod and that both dots face flywheel

36Using instructions supplied with OMC Alignment Fixture, PIN 396749, install the fixture Using OMC Torque Socket, PIN 331638, torque the connecting rod screws in stages to 30-32 ftIbs(40-43 Nm)Torquing the screws without OMC Alignment Fixture, PIN 396749, or using an incorrect procedure, could cause permanent damage to the connecting rod and crankshaftTo maintain accurate torque values, keep extension length to minimum37Thoroughly clean and degrease the crankcase mating flange of the cylinder block with OMC Cleaning Solvent and let air dry38Apply OMC Locquic Primer to the mating flange of the crankcase and let air dry39Apply OMC Gel Seal II to the crankcase mating flange of the cylinder blockThe application must cover the flange evenly and consistently without being excessiveThe application must not come within 14 in(6,4 mm) of crankcase seal rings or bearingsVI II