1990 Johnson Evinrude 120 thru 140, 185 thru 225, 300 HP, P/N 507875, Page 286Get this manual

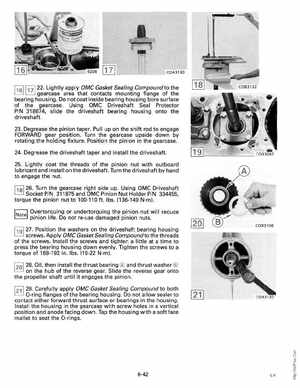

f161 r:t7l 22Lightly apply OMC Gasket Sealin9, Compound to the

gearcase area that contacts mounting flange of the bearing housingDo not coat inside bearing housing bore surface of the gearcaseUsing OMC Driveshaft Seal Protector PIN 318674, slide the driveshaft bearing housing onto the driveshaft23Degrease the pinion taperPull up on the shift rod to engage FORWARD gear positionTurn the gearcase upside down by rotating the holding fixturePosition the pinion in the gearcase24Degrease the driveshaft taper and install the driveshaft25Lightly coat the threads of the pinion nut with outboard lubricant and install on the driveshaftTurn the driveshaft by hand to engage the nut

f18l 26Turn the gearcase right side upUsing OMC Driveshaft Socket PIN 311875 and OMC Pinion Nut Holder PIN 334455, torque the pinion nut to 100-110 ftIbs(136-149 Nm)Overtorquing or undertorquing the pinion nut will reduce pinion lifeDo not re-use damaged pinion nutsf19l 27Position the washers on the driveshaft bearing housing screwsApply OMC Gasket Sealing Compound to the threads of the screwsInstall the screws and tighten little at time to press the bearing housing down evenlyTighten the screws to torque of 168-192 inIbs(19-22 Nm)1201 28Oil, then install the thrust bearing and thrust washer on the hub of the reverse gearSlide the reverse gear onto the propeller shaft until it engages the pinionf'21l 29Carefully apply OMC Gasket Sealing Compound to both O-ring flanges of the bearing housingDo not allow sealer to contact either forward thrust surface or bearings in the housingInstall the housing in the gearcase with screw holes in vertical position and anode facing downTap the housing with soft face mallet to seat the O-ringsCOB3106