1985 OMC 65, 100 and 155 HP Models Commercial Service Manual, PN 507450-D, Page 347Get this manual

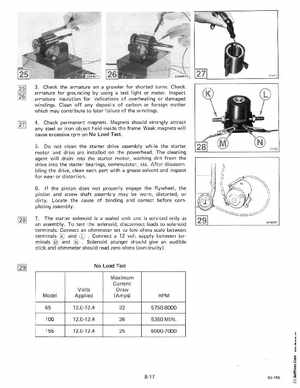

3Check the armature on growler for shorted turnsCheck armature for grounding by using test light or meterInspect armature insulation for indications of overheating or damaged windingsClean off any deposits of carbon or foreign matter which may contribute to later failure of the windings4Check permanent magnetsMagnets should strongly attract any steel or iron object held inside the frameWeak magnets will cause excessive rpm on No Load Test5Do not clean the starter drive assembly while the starter motor and drive are installed on the powerheadThe cleaning agent will drain into the starter motor, washing dirt from the drive into the starter bearings, commutator, etcAfter disassembling the drive, clean each part with grease solvent and inspect for wear or distortion6If the pinion does not properly engage the flywheel, the pinion and screw shaft assembly may be worn, distorted, or dirtyLocate the cause of binding and correct before completing assembly7The starter solenoid is sealed unit and is serviced only as an assemblyTo test the solenoid, disconnect leads to solenoid terminalsConnect an ohmmeter set to low ohms scale between terminals and Connect 12 volt supply between terminals and Solenoid plunger should give an audible click and ohmmeter should read zero ohms (continuity)